We receive questions about Japanese Kimonos and Yukatas daily. Periodically we like to share some of these to help educate others that are shopping for these wonderful robes.

What is the difference between a kimono and a yukata?

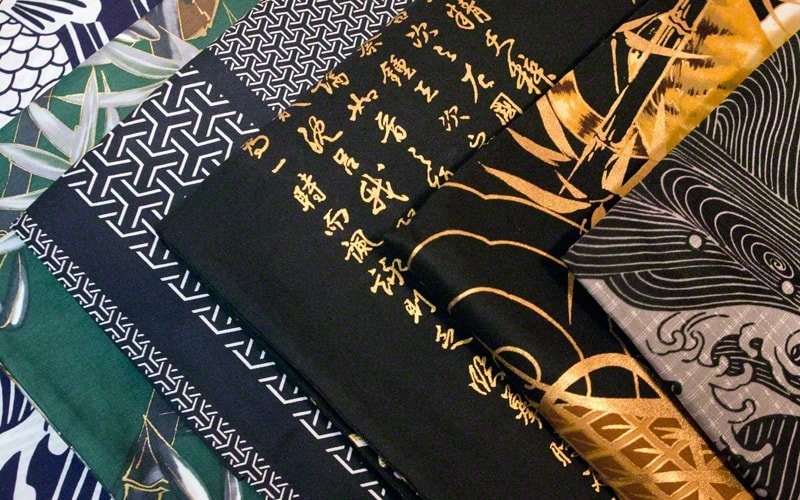

Japanese kimonos and yukatas are both traditional Japanese garments. Kimonos are more formal than yukatas and are often worn for special occasions, such as weddings or tea ceremonies. Yukatas are less formal and are often worn to outdoor events, such as festivals or fireworks displays. Both kimonos and yukatas can be either long or short. The length of a kimono or yukata is determined by the season and the occasion for which it is worn.

Kimonos are commonly made of both silk and cotton. Yukatas are made of cotton. Kimonos are typically worn in cooler months, while yukata are worn in warmer months. Today, these traditions still exist but it has become a personal choice. Yukatas are popular year-round in many parts of the world, especially in warmer climates. Kimonos are worn anytime as well. It depends on the weight of the fabric. Both are often referred to as the Best Loungewear you can find.

What is the best way to wash a kimono or yukata?

We suggest you check with the manufacturer or dealer where you purchase your garment. At Chopa – Your Kimono Source, all cotton kimonos, and yukatas are machine washable. We recommend using cold water, in a gentle cycle. This not only maintains the colors but extends the life of your robe. Many customers drip dry their robe on a hanger although it’s possible to machine dry on a low-temperature setting. Drip drying will prolong the life of the fabric.

How long does it take to receive my kimono?

We ship quickly because we know how important fast shipping is today. At Chopa, most orders are shipped within one business day, and many orders ship the same day. The earlier you place your order in the day increases the odds of shipping the same day. Your kimono ships from a warehouse in the Panhandle of Florida. We import all of our robes directly from Japan so you don’t have to wait 4-6 weeks to receive your order. Over 95% of our orders arrive at our customer’s doorstep within 3 business days, many in just two. We like to say that we give our customers the benefits of an Amazon Prime membership without the $149.00 annual fee. It’s our gift to you.

What if I don’t like the Fit of my Kimono?

That is not a problem. We offer exchanges or refunds with no questions asked. Simply contact us within 14 days of receiving your order. We will send you the simple instructions and provide you with a 14-day window to return the item. Of course, we require that the robe is unworn and in new condition.

How much is shipping?

Shipping is very reasonable. We charge a low fee of $6.95 for one kimono or yukata but provide Free Shipping anywhere in the USA if your purchase is $75.00 or more. Unlike many retailers, we don’t have exclusions. Hawaii, Alaska, and Puerto Rico are included.

Do we ship to Post Office Boxes?

We do ship to PO Boxes, however in most cases since we have to use USPS, we can often ship it quicker if you have a street address for delivery.

How do I tell which length is right for me?

We offer a great selection of kimono and yukata sizes including long, short, and plus-sizing for both men and women. For the length, we suggest using a tape measure and start at your shoulder and allow the tape to drop down your side. This is where the robe will fall on you.

Occasionally customers ask where the length should fall, but this is a personal choice. Some people like it to their ankles while others prefer it above the foot. There are also those who like shorter-length robes like our Happi Coats which fall just above, too, or below the knees. The length will be different for every person depending on your height. Buy what you like and be comfortable, that is what matters the most. Your comfort, your decision, and your kimono!

If you want to see what sizes, styles, prints, and colors are available, take a look at our online Kimono Shop. It is open 24 hours a day!